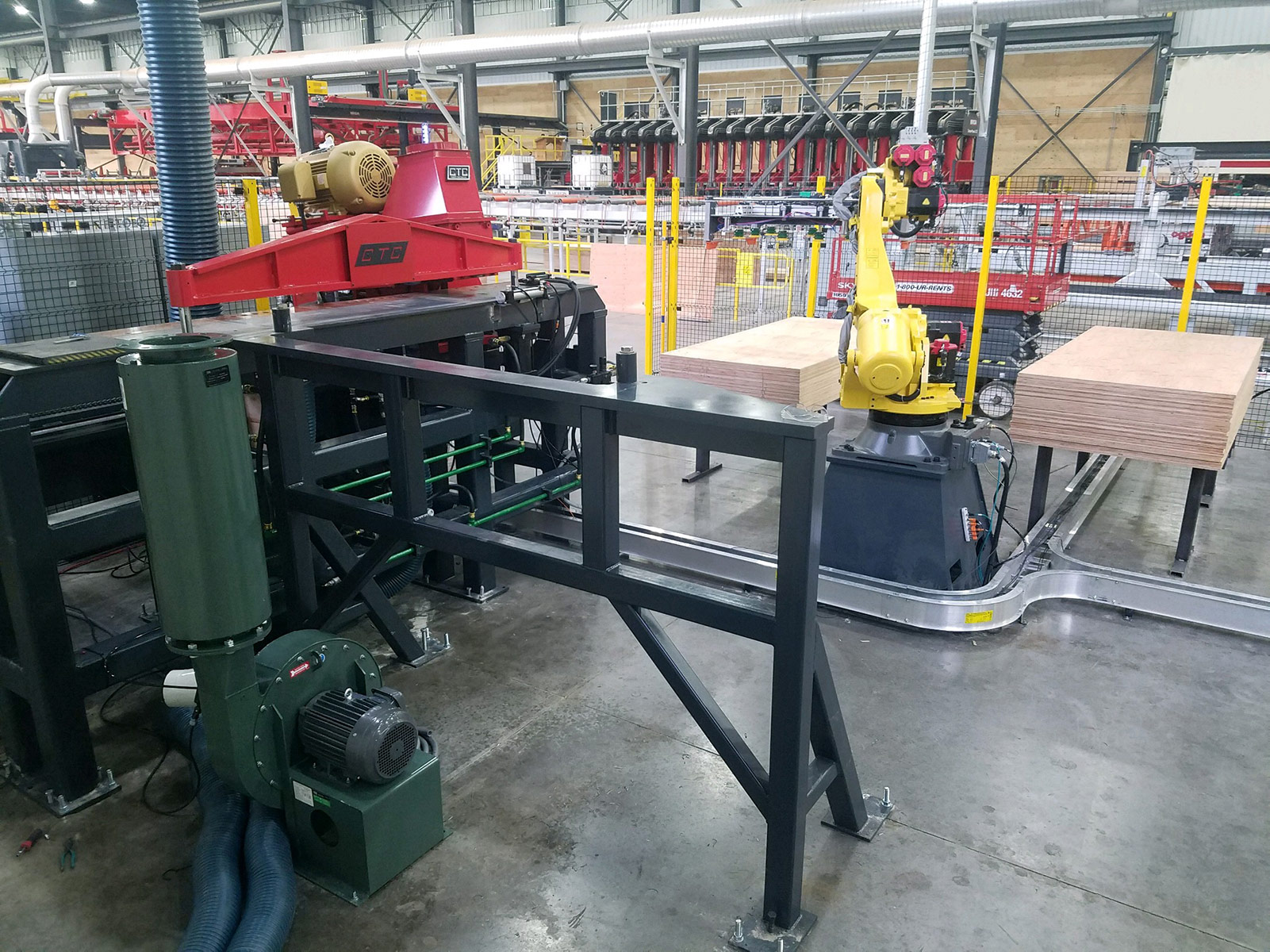

CTC Panel Scarfers are designed to meet the demanding and ever-changing panel manufacturing industry.

This panel scarfer was specifically designed to operate hand in hand with a panel handling robot. The resulting scarfed panels are then used in the precision layup and construction of Mass Plywood Panels (MPP).

Panel Scarf Features

- Manufactured of high-quality material to ensure its high durability and productivity.

- Designed to work with multiple robots feeding from multiple separate lines.

- State of the art controls provide a seamless handshake between the robots and the scarfer to prevent any unintended movement or machine cycling prior to the panel being in place.

- Single cutter head design ensures that the scarfed panels line-up perfectly every time.

- Cutter head feed speeds up to 50 fpm and panel thickness up to 1 ½”.

- Vacuum table and clamp ensures that the panels are held completely flat every time regardless of panel condition. Vacuum table generates 15 inWC of static pressure with high speed shutoff valve to limit vacuum while placing the panel.

- Single robot production of up to 2 panels per minute (4 Scarfs).